Sven Schulz, Sales Manager, In-akustik, offers a deep perspective on the brand’s core values of engineering transparency, German precision, and uncompromised signal integrity. In this interview, he discusses how In-akustik’s in-house manufacturing, proprietary innovations like the Air Helix architecture, and focus on measurable, real-world performance are driving its evolution in the high-end audio space—particularly as the brand strengthens its presence in the dynamic and fast-growing Indian market.

Tell us about In-akustik’s journey—how did the brand evolve into a benchmark in high-end audio and cable technology?

With nearly five decades of engineering heritage, In-akustik has evolved into one of Germany’s most respected manufacturers of high-performance audio, video, and multimedia connectivity solutions. What started with simple 2 x 0.5 mm² cables has grown into a comprehensive portfolio that includes high-end speaker cables, interconnects, HDMI and power cables, as well as a wide array of AV accessories.

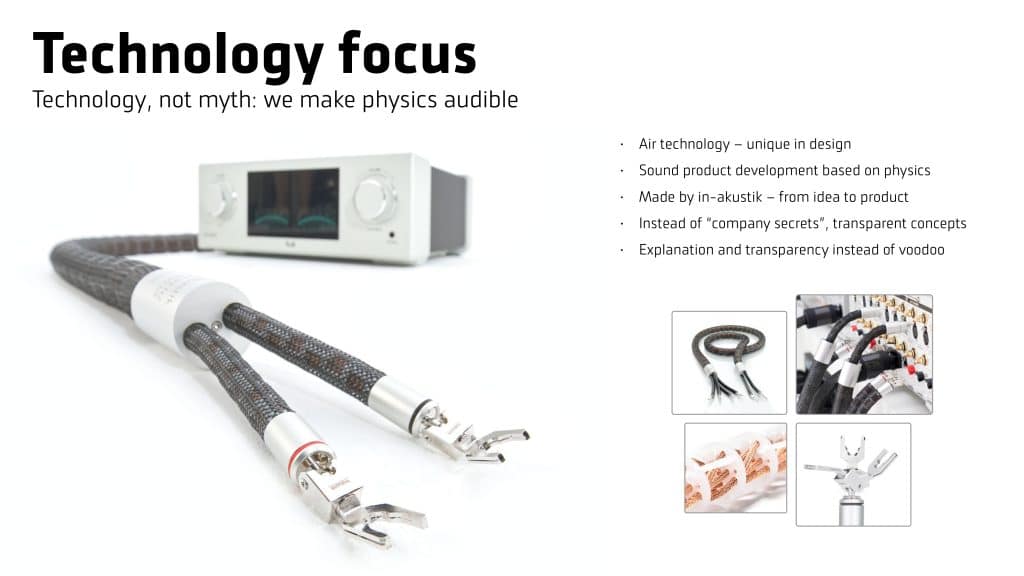

In an increasingly crowded market full of vague promises and so-called “secret technologies,” In-akustik stands firmly on a foundation of transparency and physics-based engineering. We design our products around measurable performance, with no room for pseudoscience. This philosophy is embodied in our flagship Air Helix series, where the full construction and signal path are clearly documented. Our belief is simple: if customers are investing in premium systems, they deserve to understand the technology behind it.

How does In-akustik differentiate itself from other premium audio cable and accessory brands?

The biggest differentiator is that we manufacture all of our high-end cables in-house at our facility in Germany. This gives us complete control over design, production, quality assurance, and innovation. We’re not reliant on OEM suppliers or third-party manufacturers, which means we maintain consistency from concept to final product.

Another key aspect is our commitment to real engineering. Our designs, such as the Air Helix architecture, are based on physics—not marketing hype. We don’t hide behind vague terminology; we explain exactly how our products work and why they deliver superior performance.

Finally, we are also a music label, which gives us an experiential understanding of sound. We don’t aim to create cables that add coloration—we aim to minimize losses, preserve dynamics, and deliver sound as close to the original recording as possible.

Can you explain the differences between your speaker cable offerings across the Premium, Excellence, and Reference lines?

We offer a tiered product lineup to meet varying performance needs and budgets—Star, Premium, Excellence, and Reference.

Star Line: This was our entry-level range and gained popularity in many markets, including India. However, with India now well-equipped in local cable manufacturing, we’ve shifted our focus to higher-end offerings. That said, Star speaker spools, still made in Germany, are respected for their reliability.

Premium Line: A step up in both construction and performance. These speaker cables are fully manufactured in Germany, ensuring low signal loss and robust build quality. Interconnects and HDMI cables in this line are produced via trusted long-term partners in China, adhering to our strict quality standards.

Excellence and Reference Lines: These are our flagship ranges, entirely handcrafted in Germany, designed for audiophiles and professionals who demand the highest level of performance. They feature advanced materials, proprietary geometries, and innovations like our Air Helix technology, which drastically reduces distortion and capacitance.

What core technologies does In-akustik use to maintain signal purity and minimal loss?

Signal integrity is central to our design ethos. While we use high-purity copper, our real innovation lies in how that material is applied.

Our Air Helix architecture is a standout example. Air is the best insulator aside from vacuum, and we’ve engineered a proprietary structure that suspends the conductors in air using PE spacers, achieving up to 95% air insulation. This significantly reduces capacitance and inductance, preserving signal accuracy over longer cable runs.

The conductors are arranged in a specific criss-cross pattern—not just parallel—ensuring consistent separation and eliminating signal overlap. This is especially critical in high-end systems where every nuance of sound matters.

This technology is not theoretical—it’s backed by physics and measurable results. We don’t tune cables to sound a certain way. Instead, we focus on minimizing distortion and signal degradation, letting the original recording speak for itself.

How has in-house manufacturing enhanced product quality and innovation?

Having full in-house production is a major advantage. We’re able to monitor and control every step—from sourcing raw materials to final quality checks. For instance, every finished product undergoes inspection by a second technician, never the person who assembled it. This dual-check process ensures objective, high-quality output.

It also accelerates innovation. When ideas move from R&D to production within the same facility, the feedback loop is immediate, allowing us to rapidly refine designs and maintain consistently high standards.

Can you elaborate on the evolution and impact of your Air technology?

Our journey with air insulation began over 20 years ago. Initially, we worked with polyethylene (PE) as a dielectric, but quickly realized the benefit of incorporating air. That led us to PE foam, and eventually to the development of the Air Helix design, where conductors are suspended in air using precision-engineered clips and spacers.

Maintaining the optimal distance between conductors is critical. If they’re too close, capacitance increases; too far, and inductance becomes a problem. We’ve engineered our cables to maintain ideal electrical properties, ensuring clean, accurate transmission from amplifier to speaker.

This approach results in natural, uncolored sound with exceptional detail and dynamics—and it’s particularly relevant for high-end stereo systems, where performance is audible and visible.

Are your HDMI cables ready for 4K, 8K, and beyond?

Yes, and this is an increasingly important topic. With 4K, 8K, and higher resolutions pushing bandwidth requirements, cable quality has become critical—especially over longer distances.

While short HDMI runs (1–5 meters) are still well-served by copper, anything beyond that starts to see signal degradation. That’s why we now offer fiber-optic HDMI cables, capable of transmitting full-resolution signals up to 100 meters without loss. They may look slim, but they deliver exceptional reliability and performance, ideal for professional AV and custom installations.

Beyond just selling cables, we focus on education. Many integrators underestimate the role cables play. In Germany, we run technical webinars and live demos, showing the difference between cable grades in real time. These sessions are grounded in physics, not marketing—and they empower professionals to make informed choices.

What is your strategic portfolio plan for the Indian market?

India is an exciting and fast-maturing market. While the entry-level segment is well-served by local and mass-market offerings, our focus is firmly on the premium and audiophile segments—where performance truly matters.

We’re starting with the Premium line and gradually expanding into the Excellence and Reference ranges. Our products are available for live demo at partner showrooms, and we’re building a network across both metro and Tier 2/3 cities—including Mumbai, Kolkata, Hyderabad, and Raipur.

Our cables are already being integrated into high-end AV and stereo setups alongside brands like ELAC and Fyne Audio. These customers recognize the impact cables have on system performance, both audibly and visually—particularly in stereo systems, where cables are not hidden but proudly displayed.

We’ve also been able to maintain fair, stable pricing, which positions us as a cost-effective yet high-performance alternative to other premium brands affected by tariffs and global pricing fluctuations.